OUR PROJECTS

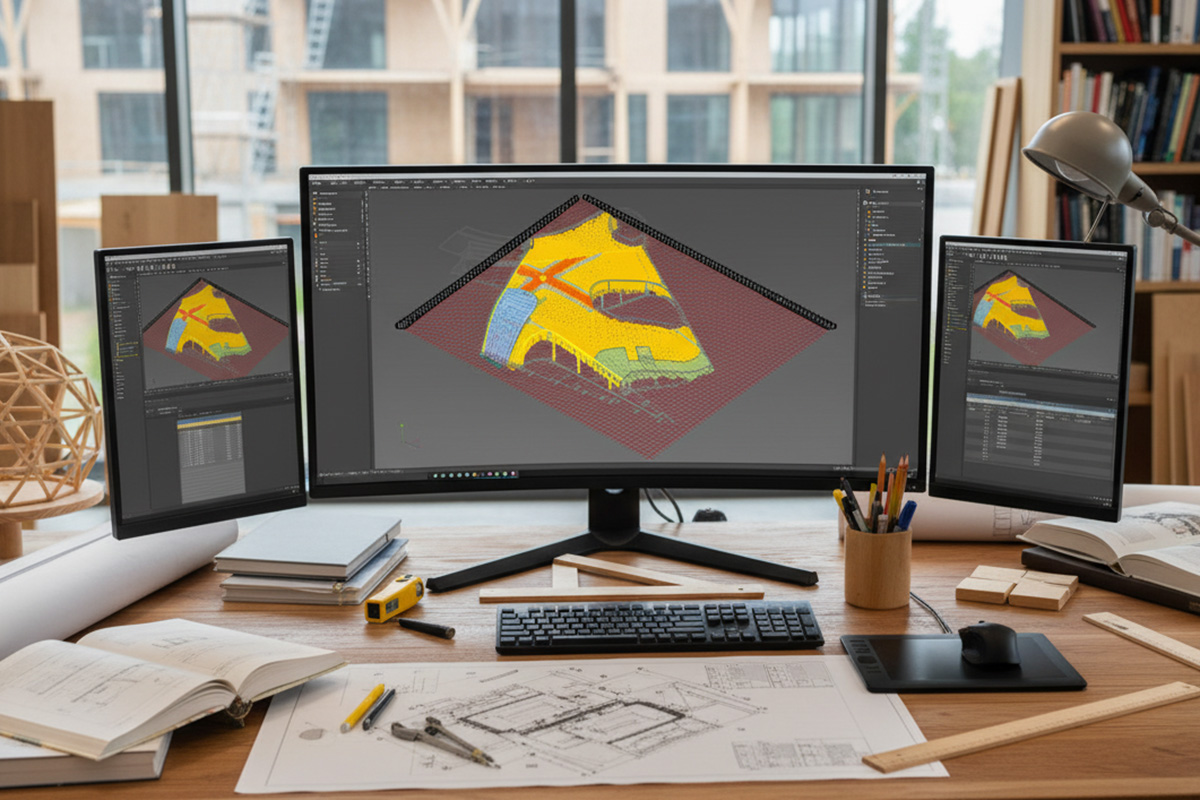

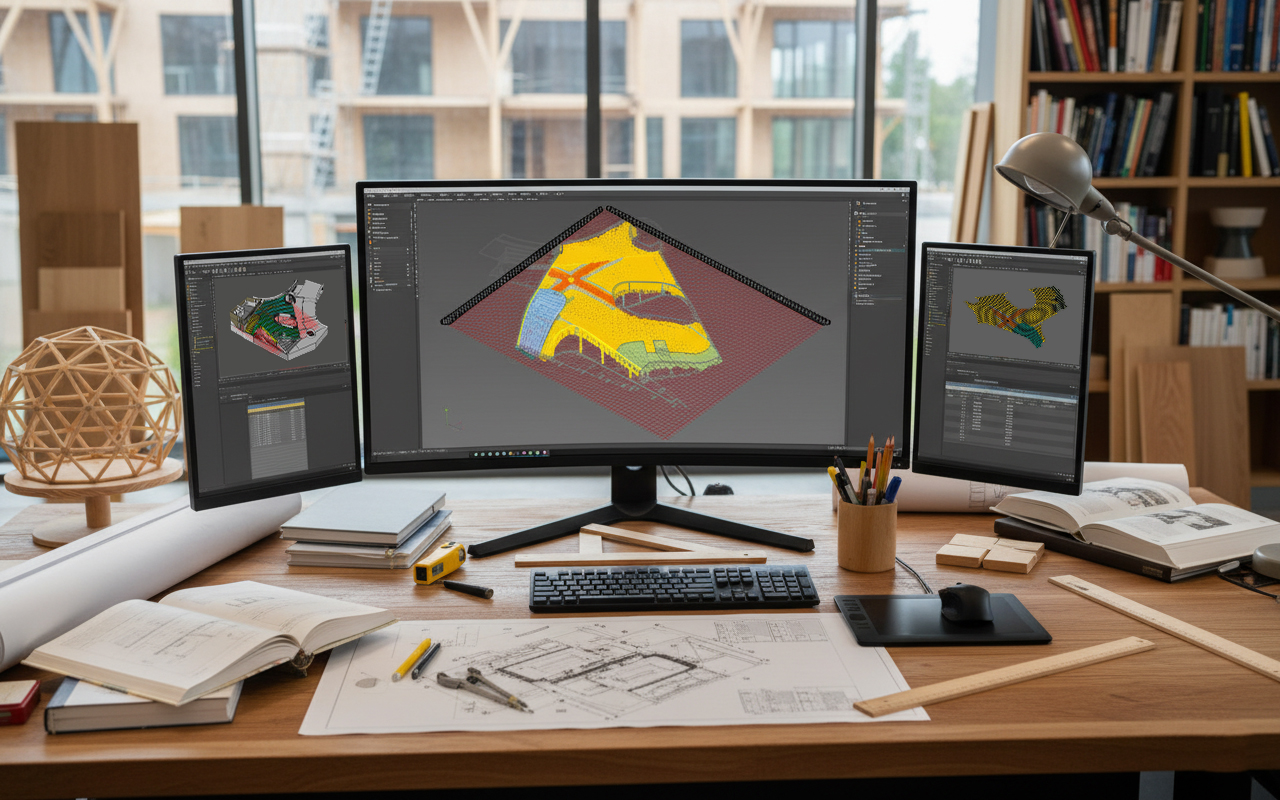

Digital engineering and parametric modeling serving timber construction

TC2 expertise at the heart of timber projects

Each project entrusted to TC2 is driven by a shared goal: to reconcile architectural complexity, digital precision, and constructive feasibility.

With full mastery of 3D modeling, CNC programming, and parametric systems, TC2 supports architects, engineering offices, and manufacturers in bringing their most ambitious ideas to life.Our work covers every stage of the digital process (from design to fabrication) to ensure reliable, optimized, and perfectly executed structures.

Each model designed by TC2 becomes a genuine production tool, ensuring seamless continuity from concept to material.

CURRENT PROJECTS

These ongoing projects illustrate TC2’s ability to integrate digital tools into highly technical construction sites, in collaboration with leading partners in the timber sector.

Shakespeare Project

Québec (Canada)

3D modeling and CNC programming for timber. In partnership with Art Massif, TC2 develops the 3D modeling and CNC programming of double-curved edge beams, with automatic machining path generation and coordination of the gluing process.

Williams College Museum

Boston (États-Unis)

Parametric modeling and CNC panel layout for CLT panels

Working alongside Nordic Structures, TC2 is responsible for the modeling and automated layout of 273 cold-bent CLT panels, ensuring geometric precision and smooth continuity from design to fabrication.

Early childhood care center

Issy-les-Moulineaux (France)

Parametric modeling and automation of the timber lattice

An emblematic project bringing together Simonin and Spie, for which TC2 modeled and automated the production of more than 1,200 unique pieces forming the three-dimensional timber lattice of the façade.

COMPLETED PROJECTS

Villa Punta Cana

Dominican Republic

CNC programming and production monitoring for curved timber components

Development of a custom machine program to adjust CNC toolpaths according to the actual wood deformations and to optimize the gluing process monitoring.

Ehnen Project

Luxembourg

Modeling parametric modeling and timber CNC workflows in collaboration with the company Simonin

TC2 developed the parametric modeling of the beams and joints, optimized the metal connectors, and transferred the digital data directly to the CNC machines, ensuring fabrication without manual re-entry.

APPROACH

TC2

Each project undergoes a thorough technical analysis:

- 3D modeling to visualize and validate the geometry of the structures,

- CNC programming to convert the model into precise production files,

- Parametric systems to automate, adapt, and secure digital processes.

TC2 operates at the intersection of design, technology, and timber fabrication, delivering agile and sustainable digital engineering.

Each project is a demonstration of precision

Do you have a complex timber project requiring parametric modeling, CNC preparation, or custom digital optimization?

Contact TC2 to discuss your technical needs and benefit from expert support, from design to fabrication.