EARLY CHILDHOOD CARE CENTER PROJECT / Issy-les-Moulineaux (France)

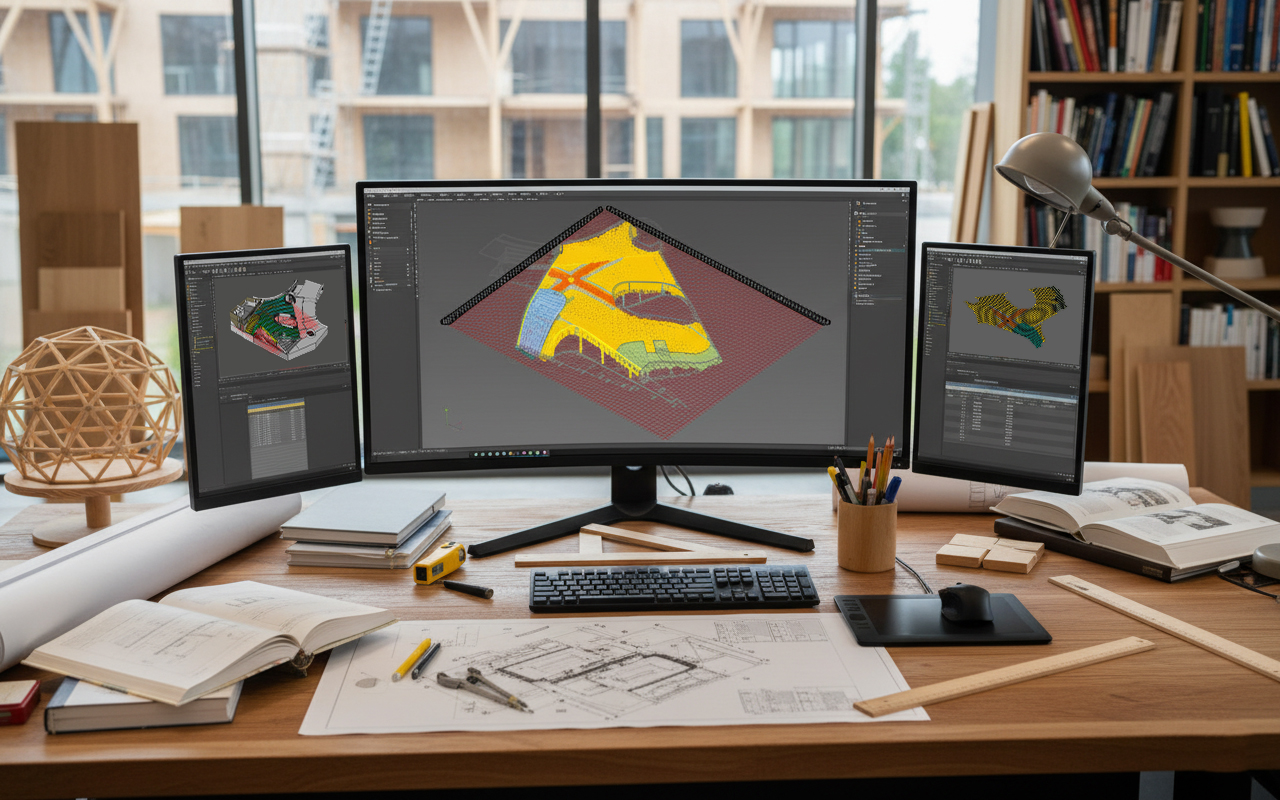

Parametric modeling and automation of the timber lattice.

PROJECT CONTEXT

The Issy-les-Moulineaux early childhood care center project, carried out in partnership with Simonin and Spie, featured a three-dimensional timber lattice made up of more than 1,200 unique components.

This architectural challenge required precise digital management to model, produce, and assemble each element flawlessly.TC2 was involved in designing the complete modeling of the lattice, streamlining production, and automating the preparation of machining files, ensuring reliable and repeatable execution.

This project showcases TC2’s expertise in transforming complex architectural geometries into precise, production-ready parametric models.

MISSION AND TC2’s interventions

TC2’s involvement covered the entire process of modeling and fabrication preparation.

Main technical tasks:

- Complete 3D modeling of both finished and raw components, including accessories and connections,

- Development of a dedicated Python script to control the modeling process simultaneously in Rhino 3D and Cadwork 3D.

- Automation of panel layout and numbering of components to simplify production tracking,

- Implementation of a centralized database managing the parameters of each component (thickness, position, orientation, type of joint).

This parametric approach made it possible to move from a free-form geometry to a fully controlled production system, while preserving the architectural design intent.

Technologies and tools used

The project is based on an interconnected digital workflow:

3D modeling

Rhino 3D for geometry and advanced modeling,

Cadwork 3D for machine file generation and technical documentation.

Parametric system

Grasshopper for parameter management and iterative design,

Python for creating custom tools for data transfer and generation.

The integration of these tools enabled seamless continuity between design and fabrication, minimizing errors and data loss between software platforms.

Results and benefits

Thanks to the parametric method and the developed scripts:

-

- The 1,200 components were automatically generated from the 3D model,

- The machine preparation time was significantly reduced,

- The assembly precision allowed for rapid installation with no on-site adjustments,

- The shape variability was preserved while ensuring industrial feasibility.

The Issy-les-Moulineaux project illustrates the power of parametric modeling in reconciling architectural freedom with constructive precision.

Your project for the future

Are you working on a façade, a lattice, or a complex timber structure requiring parametric modeling, CNC programming, or an automated panel layout system?

Contact TC2 to benefit from expert technical support and optimized production implementation.

Answers to your questions about our expertise and methods

What is a 3D timber lattice?

A timber lattice is an openwork grid of wooden components used to filter light or structure a façade.

In the Issy-les-Moulineaux project, each piece had a unique geometry, requiring a complete parametric model to ensure both feasibility and repeatability.

What is automated panel layout?

Panel layout involves distributing, identifying, and numbering each component according to its exact position within the project.

Thanks to the automation developed by TC2, this process is generated directly from the 3D model, eliminating potential errors and simplifying on-site assembly.

What are the advantages of parametric modeling?

It makes it possible to manage hundreds of different components from a single source model.

Adjustments are performed automatically, which reduces design time and ensures perfect consistency across all fabrication files.

What are the concrete benefits for the client?

- Time savings in both design and production,

- Reduced error-related costs and on-site rework,

- Smooth coordination between architects, engineers, and manufacturers,

- Consistent visual and structural quality throughout the entire project.