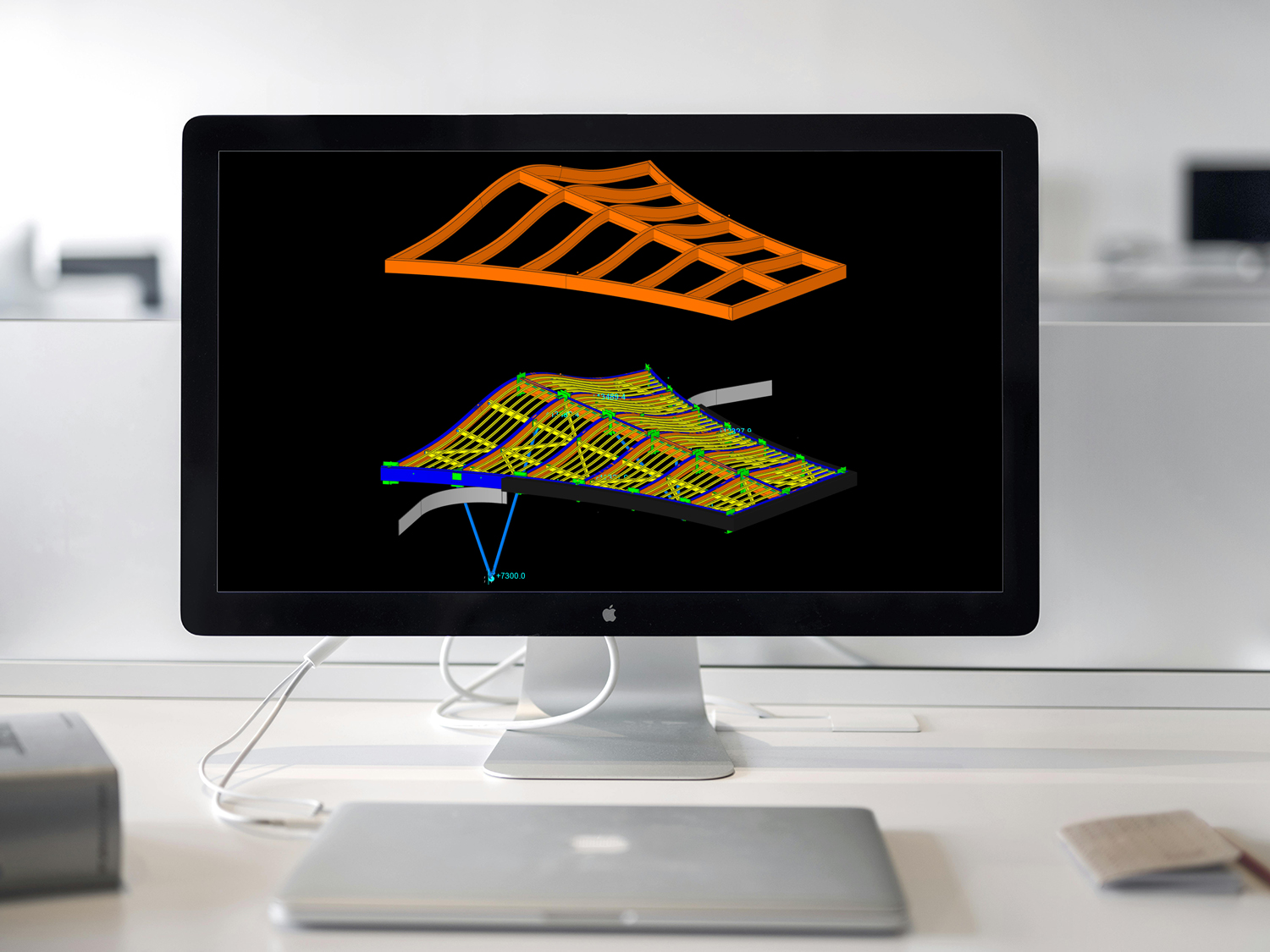

Villa Punta Cana / Dominican Republic

CNC programming and production monitoring for curved components.

PROJECT CONTEXT

Designed for an architect’s villa in Punta Cana, this project stands out for its double-curved timber structures and non-standard assemblies.

TC2 was commissioned to carry out the complete CNC programming of the components, with the goal of achieving maximum machining precision despite the natural deformations of the wood.

At the heart of the project: the implementation of an intelligent digital process, directly linking 3D modeling to actual fabrication.

An emblematic project showcasing TC2’s expertise in bridging parametric design and precision timber fabrication.

MISSION AND TC2’s interventions

The TC2 team was involved in both programming and workshop quality control, following a continuous optimization approach.

Main technical tasks:

- Development of a custom CNC program integrating an automatic correction algorithm to adjust toolpaths according to actual deformations,

- Optimization of gluing sequences to ensure the dimensional stability of the curved components,

- On-site production monitoring to validate machining quality and fine-tune fabrication parameters,

- Coordination with the local subcontractor for the implementation and inspection of gluing operations.

This custom digital approach enabled a stable, fast, and repeatable production process, essential for timber components with variable geometry.

Technologies and tools used

The Villa Punta Cana project is based on a fully integrated digital workflow, from model to machine:

3D modeling

Rhino 3D for geometric design and 3D file preparation.

CNC programming

Techno Wood / Cadwork for machine simulation and toolpath execution,

TC2 internal tools for dimensional control and tolerance management.

Parametric system

Grasshopper and Python for developing correction scripts and CNC export automation.

The integration of these technologies made it possible to connect design, fabrication, and quality control within a single digital environment.

Results and benefits

The implementation of TC2’s digital solutions made it possible to:

- A 20% reduction in machine preparation time,

- A significant improvement in machining accuracy, despite the natural variations of the material,

- An increased stability of the gluing process, thanks to rigorous monitoring and digital stress analysis,

- A better coordination between design, production, and assembly, enhancing overall project reliability.

This project illustrates TC2’s ability to connect modeling, fabrication, and quality control within an integrated digital approach.

Your project for the future

Are you developing a project that requires precise 3D modeling, custom CNC programming, or the implementation of a parametric system tailored to your production constraints?

Contact TC2 to benefit from comprehensive technical support, from design to fabrication.

Answers to your questions about our expertise and methods

What is custom CNC programming?

It is a specific development that adapts machine toolpaths to the project’s real constraints (irregular shapes, wood deformations, variable angles).

This approach ensures precise and repeatable machining, regardless of the level of complexity.

Why adjust toolpaths based on deformations?

Wood, being a living material, can slightly deform during fabrication or gluing.

The algorithm developed by TC2 automatically adjusts CNC toolpaths to compensate for these variations, ensuring the geometric accuracy of each component.

What are the benefits for the client?

- Reduced machining time and minimized manual rework,

- Improved assembly accuracy,

- Increased reliability between the 3D model and on-site reality,

- Optimized production and reduced waste.

TC2 transforms technical constraints into opportunities for efficiency and performance for timber manufacturers.