EHNEN PROJECT / Luxembourg

Parametric modeling and timber CNC programming by TC2.

PROJECT CONTEXT

The Ehnen Project, located in Luxembourg, showcases a strong collaboration between TC2 and the company Simonin.

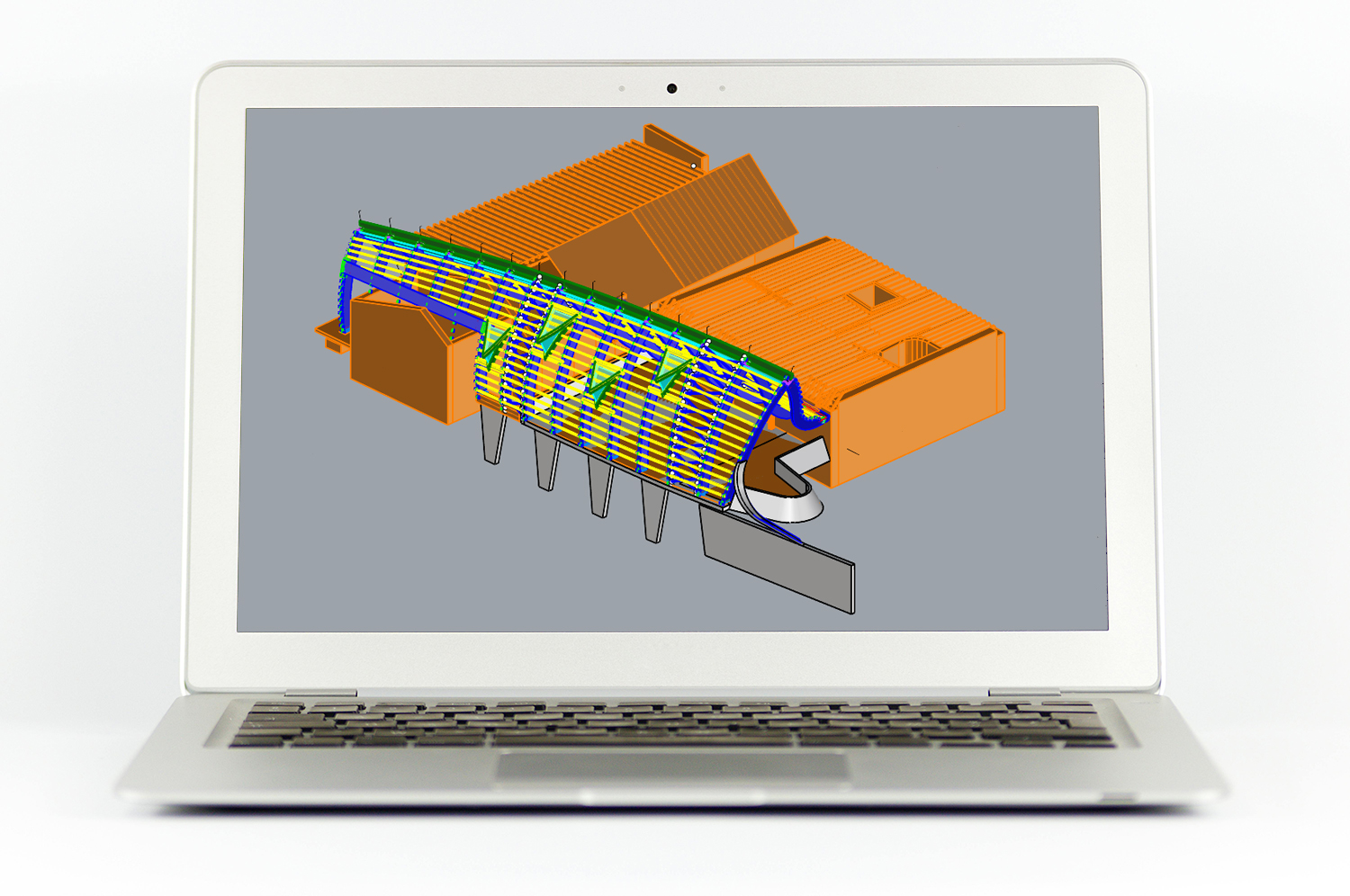

The main challenge focused on the modeling of beams and joints as well as the rationalization of metal fittings, within the framework of a complex architectural structure.

TC2 leveraged its expertise in 3D modeling and CNC programming to develop a complete digital model, ensuring the project’s reliability, execution speed, and structural performance.

This project highlights TC2’s ability to transform an architectural design into a production-ready model through complete and rigorous digital integration.

MISSION AND TC2’s interventions

As part of its mission, TC2 carried out the parametric modeling of the beams and joints, as well as the timber CNC programming required for their fabrication.

The chosen approach relied on precise management of structural parameters and machining constraints to ensure accurate fitting between the timber and metal components.

Main technical interventions:

- Creation of dynamic models adaptable to the project’s constraints,

- Optimization of beams and fittings to minimize waste and rationalize material use,

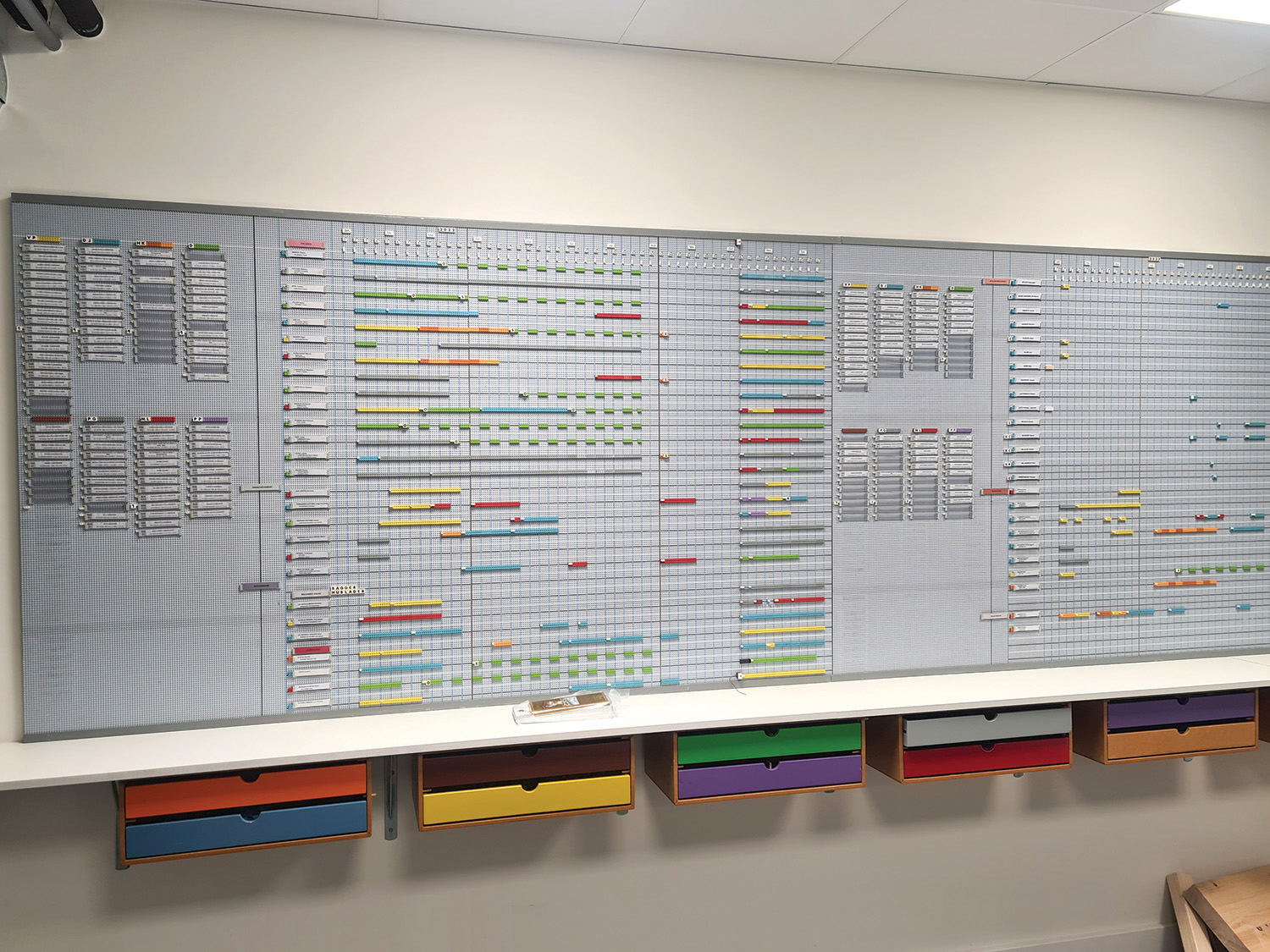

- Automation of panel layout and component identification for streamlined tracking,

- Direct transfer of digital models to CNC machines to ensure a continuous production workflow.

Each stage was designed to ensure perfect consistency between digital design, fabrication, and on-site installation.

Technologies and tools used

The project is based on an integrated digital workflow connecting design, analysis, and fabrication.

TC2 used a set of interoperable tools tailored to the project’s requirements:

3D modeling

Rhino 3D for geometric modeling and management of complex shapes

CNC programming

Cadwork and Techno Wood for machine preparation, machining simulation, and CNC toolpath control

Parametric system

Grasshopper and Python for developing parametric scripts that automate geometric adjustments.

This mastery of parametric and digital tools demonstrates TC2’s ability to connect engineering, production, and assembly within an optimized manufacturing process.

Results and benefits

Thanks to this integrated approach, TC2 enabled:

- A rationalization of fittings and joints, reducing variations and simplifying logistics,

- A reduction in machine preparation time thanks to automated exports,

- An increased machining precision, eliminating manual adjustments,

- A seamless digital workflow, from the 3D model to the finished component.

The Ehnen project demonstrates the relevance of parametric modeling and CNC programming in ensuring the reliability and durability of contemporary timber structures.

Your project for the future

Are you looking for a partner capable of modeling your complex timber structures, ensuring the CNC programming of your components, or designing a custom parametric system?

Contact TC2 to discuss your needs and benefit from expert technical support, from design to production.

Answers to your questions about our expertise and methods

What is parametric modeling applied to timber?

Parametric modeling consists of creating a 3D model driven by parameters (dimensions, angles, spacing, sections, tolerances, etc.).

Any modification is automatically reflected throughout the entire model, ensuring geometric consistency and assembly accuracy.

In the field of timber construction, this approach makes it possible to simulate and optimize structures even before fabrication, while anticipating production constraints.

What is panel layout?

Laying-out refers to the methodical arrangement of components on a plan or surface prior to fabrication.

In the case of a timber structure, this means organizing and numbering each element (beam, fitting, base plate, etc.) according to its exact location within the project.

TC2 automates this process using parametric scripts: the layout is generated directly from the 3D model, ensuring error-free identification and time savings both in the workshop and on site.

Why use CNC programming in timber construction?

- CNC programming (Computer Numerical Control) makes it possible to convert a 3D model into precise instructions for machining tools.

Each drilling, groove, or cut is automatically generated from the parametric model.

This method ensures faithful execution of the original design, reduces manual adjustments, and improves quality and repeatability in production.