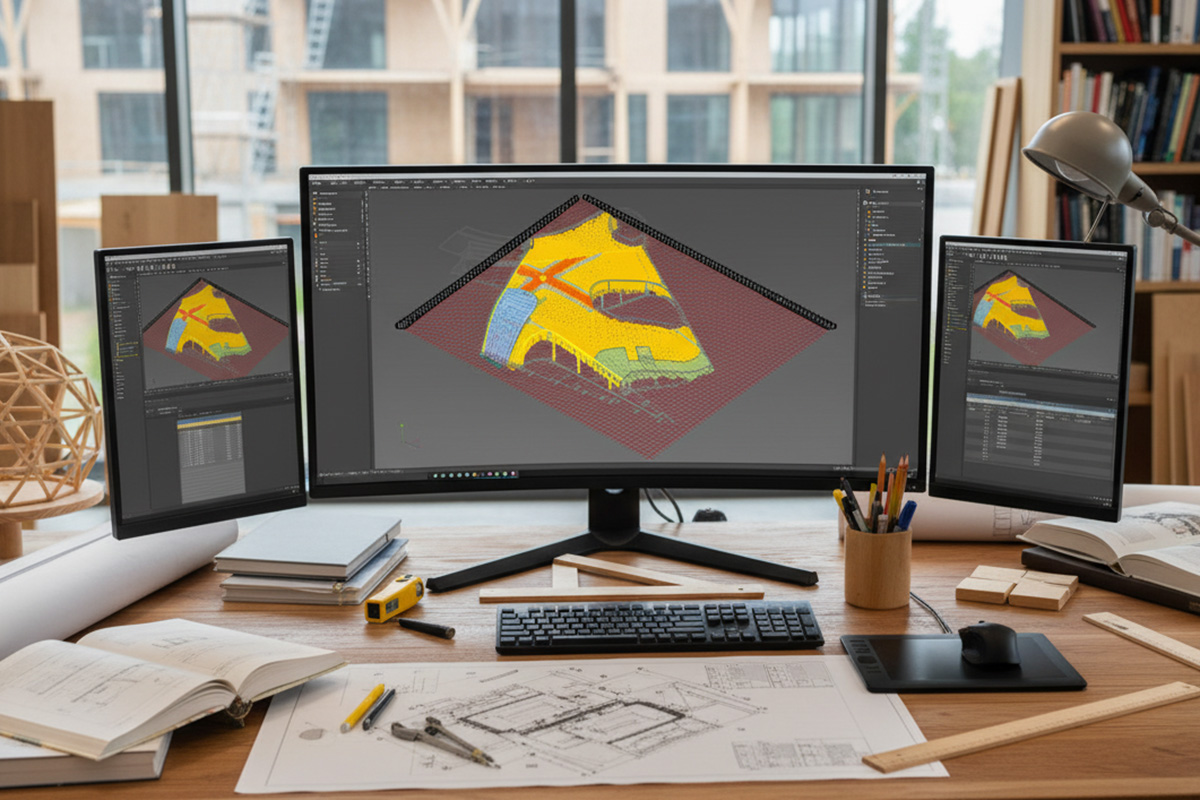

Parametric system

Digital intelligence at the service of flexibility and performance

The parametric system is at the heart of TC2’s digital approach.

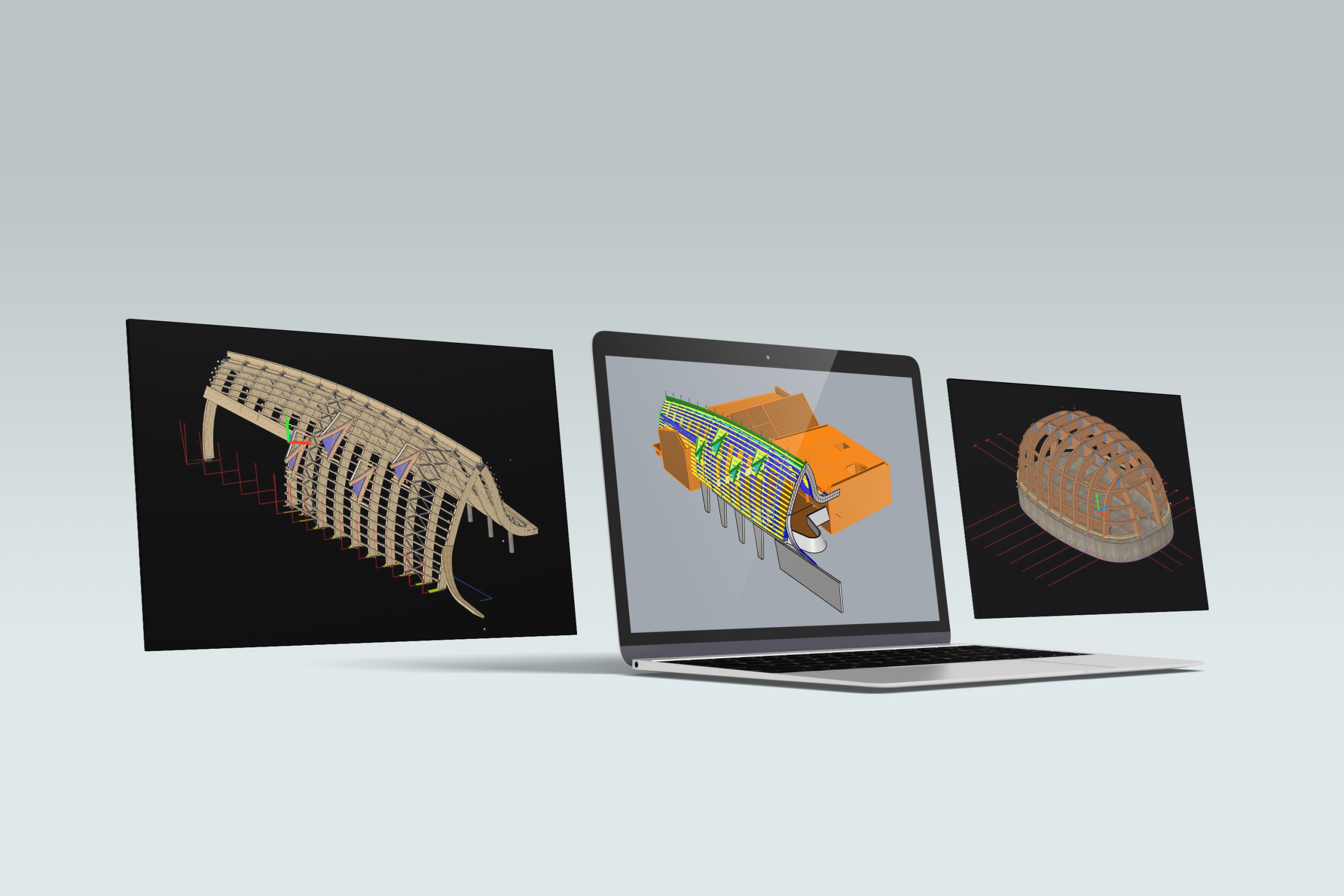

It allows the creation of evolving and adaptive models, capable of automatically recalculating according to project constraints (dimensions, angles, materials).

This approach combines algorithmic logic, structural engineering, and timber expertise, ensuring agility and optimization.

At TC2, parametrics is not a trend: it is a sustainable working method linking design, fabrication, and innovation.

CNC programming at TC2 embodies the balance between digital rigor and technical expertise, achieving exceptional precision.

TC2 Expertise

- Design of custom parametric algorithms,

- Automation of modeling and layout,

- Integration of structural and machining constraints,

- Adaptation of models to production realities,

- Interface with CNC and manufacturing software.

Tools and technologies

- Grasshopper (Rhino 3D) for parametric logic,

- Python for advanced algorithm development,

- Connections with Cadwork and Techno Wood,

Applications and projects

Results and benefits

- Significant time savings in design,

- Reduction of human errors,

- Adaptability to last-minute changes,

- Overall consistency between variants and assemblies,

- Contribution to more sustainable and efficient design.

Move to parametric design

Do you want to design a custom parametric system for your complex timber projects?

Let’s discuss your parametric needs.

Answers to your questions about our expertise and methods

What is a parametric system applied to timber?

It is an intelligent model that automatically updates according to project constraints, ensuring flexibility and precision.

Which tools does TC2 use for parametrics?

Mainly Grasshopper and Python, interconnected with Rhino and manufacturing tools.

What are the concrete benefits for the client?

Evolving models, improved responsiveness, and a significant reduction in design and fabrication time.