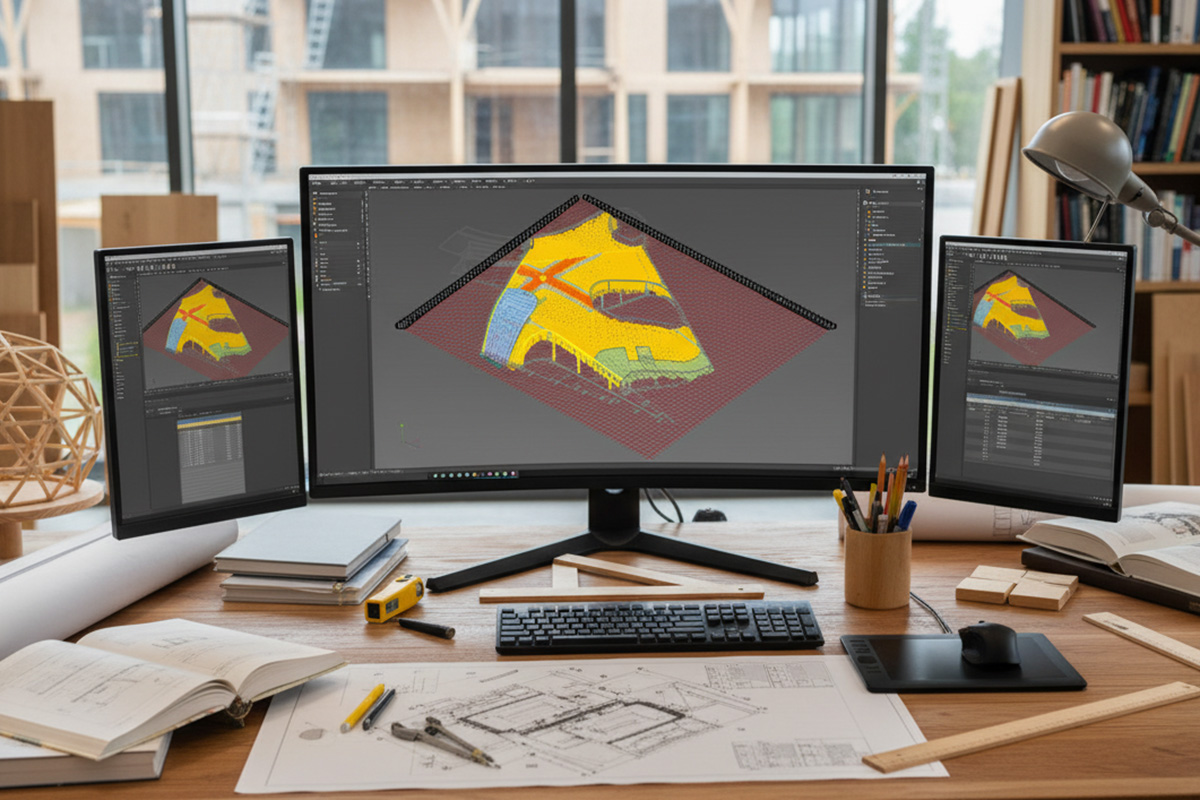

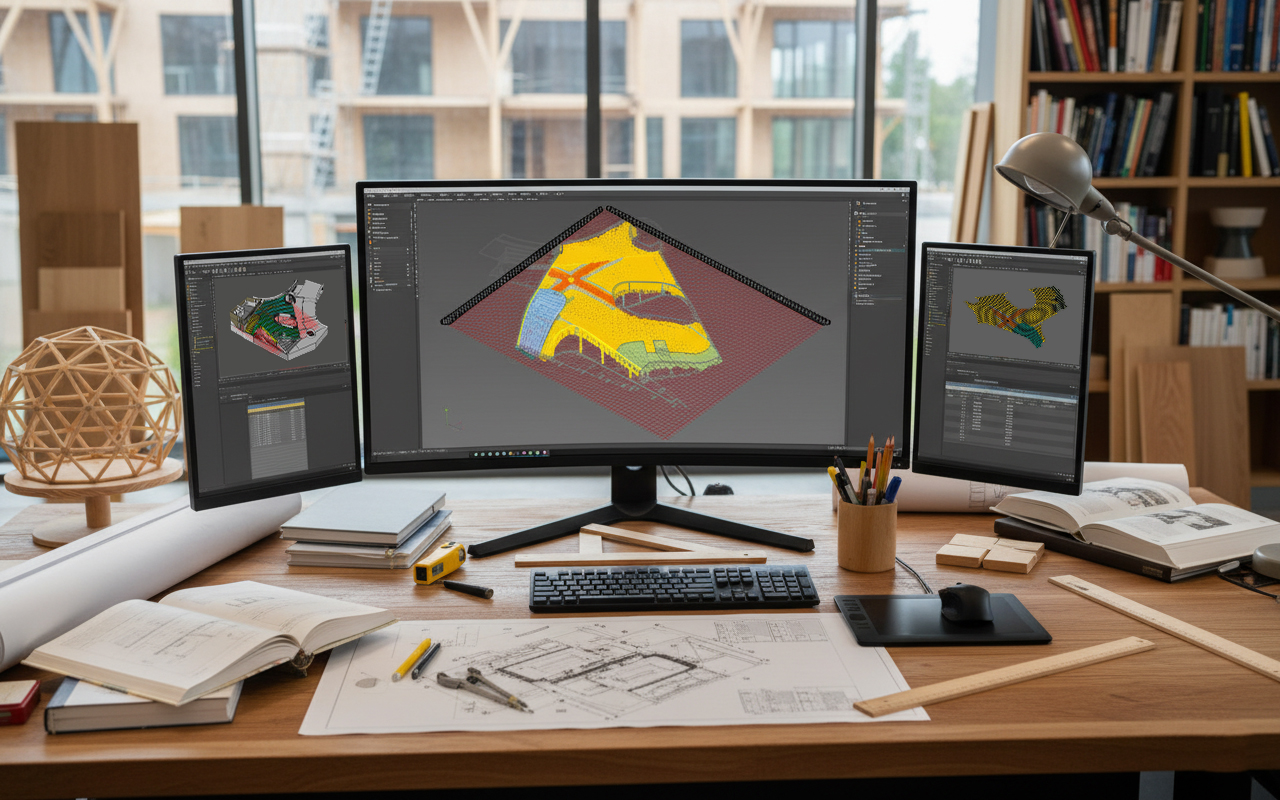

3D MODELING

Design, anticipate, master every detail

At the heart of TC2’s approach, 3D modeling is the starting point of any optimized timber construction.

It makes it possible to design, visualize, and anticipate interactions between materials, structures, and manufacturing processes.

With more than 20 years of experience in timber engineering, TC2 places digital modeling at the service of durability, performance, and construction precision.

At TC2, each 3D model becomes a living digital mock-up, connected to production tools and to the environmental requirements of the project.

Skills and expertise

- Creation of precise geometric models, integrating machining tolerances and constraints,

- Modeling of raw and finished components, including their assemblies and accessories,

- Integration of mechanical, thermal, and structural constraints,

- Coordination between engineering offices, workshops, and construction sites via a centralized model,

- Preparation of data for CNC programming and parametric systems.

Tools and technologies

- Rhino 3D for advanced geometric modeling,

- Grasshopper for automation and parametric generation,

- Python for custom script development,

- Cadwork / Techno Wood for continuity between design and fabrication.

Applications and projects

Results and benefits

- Reduction of design errors,

- Optimization of production timelines,

- Clear and shared project vision,

- Smooth preparation for CNC and parametric stages,

- Contribution to more efficient and sustainable construction.

Need precise and reliable modeling?

TC2 designs your 3D models with optimal geometric accuracy to anticipate every stage of fabrication.

Contact us to turn your ideas into digital models that can be used right from the design phase.

Answers to your questions about our expertise and methods

Why is 3D modeling essential in timber construction?

It allows you to visualize and adjust structures before fabrication, reducing errors and optimizing material usage.

Does TC2 use formats compatible with CNC machines?

Yes, all models are designed to be interoperable with timber production equipment (Techno Wood, Homag, Biesse, etc.).

Does 3D modeling promote sustainability?

Yes: by anticipating constraints and optimizing cuts, it reduces material waste and errors, contributing to more responsible construction.